Cream Cheese and Labneh Production Lines: Industrial Solutions and Technological Approach

Cream cheese and labneh are two popular dairy products, widely consumed in both breakfast culture and the bakery sector. With their smooth texture, slightly tangy flavor, and versatile applications, they hold a significant place in both industrial and household kitchens. Modern food industry technologies now enable the production of these products in highly hygienic, efficient, and continuous systems through turnkey production lines.

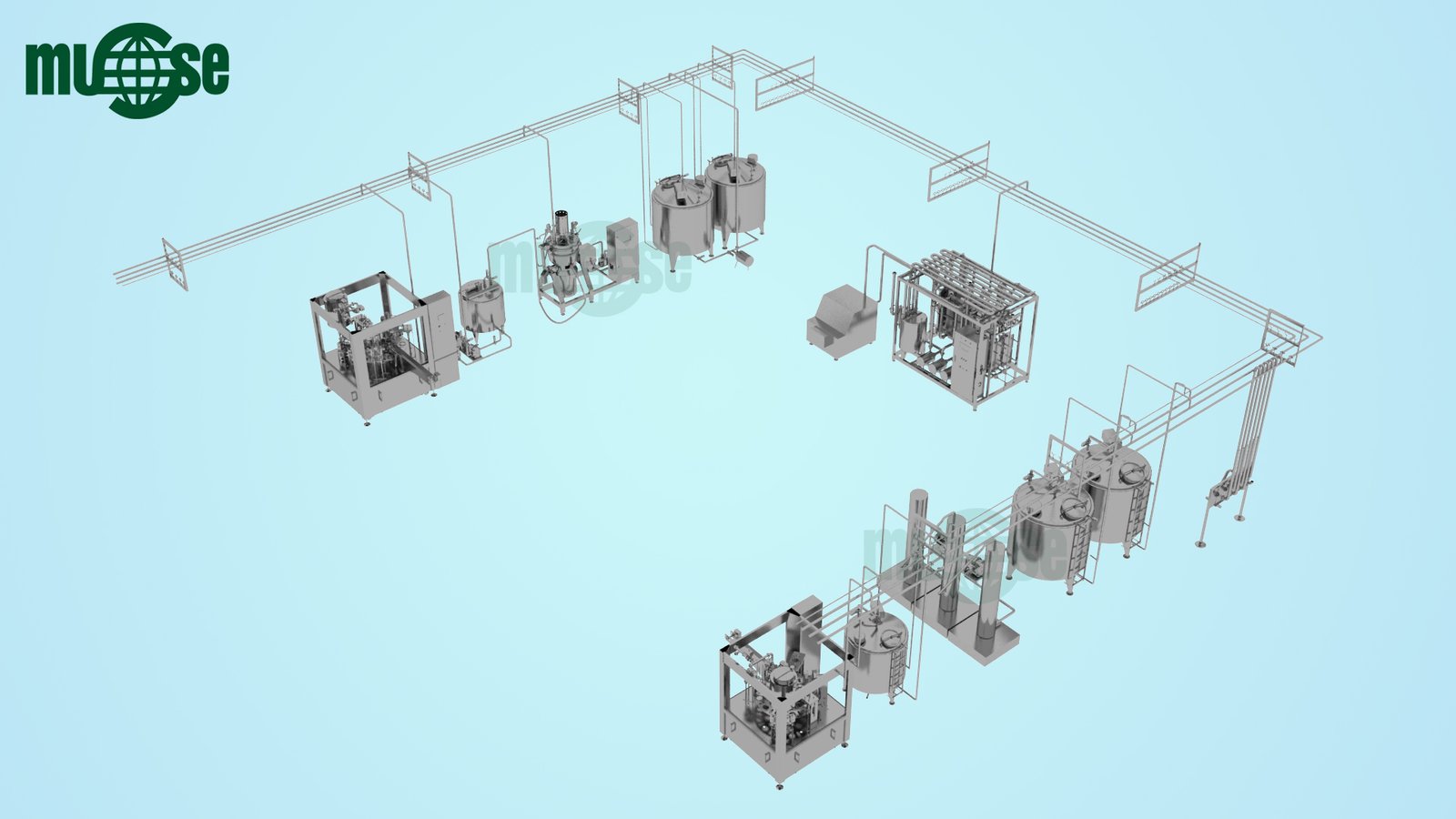

Muse Food Tech’s Cream Cheese and Labneh Production Lines offer an integrated solution covering every stage, from raw milk processing to final packaging.

Milk Preparation

The production begins with raw milk storage and clarification:

-

Milk Storage Tanks: Raw milk is stored at +4 °C in cooled tanks.

-

Separator (Cream Separation): Fat content is adjusted according to product standards.

-

Standardization Unit: Desired fat and dry matter levels are achieved.

For cream cheese, fat content is usually adjusted to 18–24%, while for labneh it remains around 10–14%.

Heat Treatment (Pasteurization)

A critical food safety step.

-

Plate or Tubular Pasteurizer: Milk is heated to 85–95 °C and then rapidly cooled.

-

Ensures microbial safety and extends shelf life.

Culturing and Fermentation

-

Starter Culture Addition: Lactic acid bacteria reduce milk pH, giving the product its tangy flavor and texture.

-

Fermentation Tanks: Process carried out under controlled temperature (30–35 °C).

-

Fermentation is stopped when the target pH of 4.6–4.7 is reached.

Whey Separation

The key difference between cream cheese and labneh lies here.

-

Ultrafiltration (UF) Systems or Filter Bags / Filtration Units are used.

-

Whey is separated and the product is concentrated.

-

UF technology increases yield and ensures homogeneous texture.

Mixing and Homogenization

-

Mixing Tanks: Optional addition of cream, milk powder, or stabilizers.

-

High-Pressure Homogenizer: Provides a smooth and creamy structure.

Cooling and Resting

The product is cooled down to +4 °C and rested to stabilize its structure.

Filling and Packaging

-

Automatic Filling Machines: Fill into plastic cups, glass jars, or aluminum foil-sealed containers.

-

Hygienic Packaging minimizes contamination risks.

-

The line is designed for flexible formats and multiple packaging options.

CIP (Clean-in-Place) Systems

Hygiene is crucial for quality. Muse Food Tech lines are equipped with automatic CIP systems to ensure efficient cleaning and disinfection.

Technological Advantages

-

High Efficiency: Increased yield with UF technology.

-

Standardized Quality: Automated process control ensures consistent taste and texture.

-

Hygienic Design: Compliant with European food safety standards.

-

Flexible Production: Same line can produce cream cheese, labneh, and strained yogurt.

Cream cheese and labneh production lines are not just part of dairy processing, but also strategic solutions for meeting growing consumer demands. With its turnkey plant solutions, Muse Food Tech provides producers with efficiency, safety, and sustainability advantages.