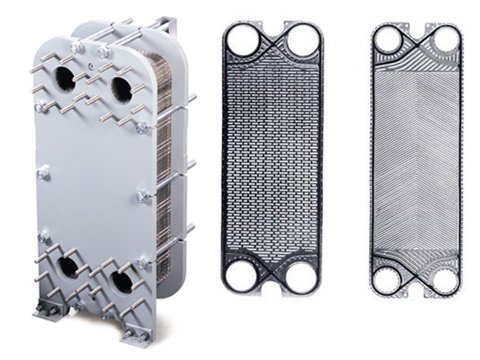

Pasteurization is a process in which liquids are heated either cold or hot to eliminate all pathogens. During this process, the gaskets on the plates ensure that the hot and cold liquids do not mix. The characteristics of the heating system to be used depend entirely on the product requirements and the desired results. The system is designed based on factors such as product inlet-outlet temperatures, operating pressure, acceptable pressure losses within the heat exchanger, heating capacity, and the type and quantity of the liquids.

In all our machines, we prefer equipment with high-precision control systems. The panels housing the circuits or electrical control equipment are designed to be resistant to water and steam. All measuring instruments are carefully selected to meet high hygiene standards and precision.

In the pasteurization process, two different control system options are available:

Touchscreen PLC System: In this system, all valves are of pneumatic type. The milk processing process can be easily programmed depending on the product type.

PID System with Manual Valves: Unlike the PLC system, this system uses manual-type valves. However, the heating valve is different and utilizes a proportional valve. In this system, the desired temperature can be set and maintained.

All switches inside the panel are of the highest quality. Cables and other components are arranged neatly within the panel. All materials are carefully selected to ensure high durability and tolerance in the switches.

All software is developed by Muse Food Tech, providing a flexible and customized software infrastructure.

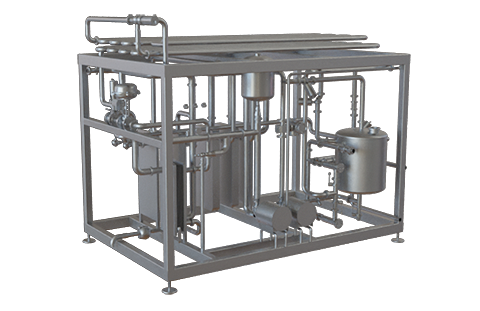

PLATE PASTEURIZER

PLATE HEAT EXCHANGERS

BRINE PASTEURIZER

ELECTRIC PASTEURIZATION TANK

ELECTRIC PASTEURIZERS

PLATE ICE CREAM PASTEURIZER

HONEY PASTEURIZER

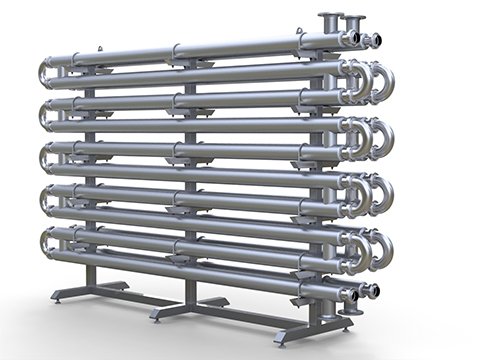

TUBULAR HEAT EXCHANGER