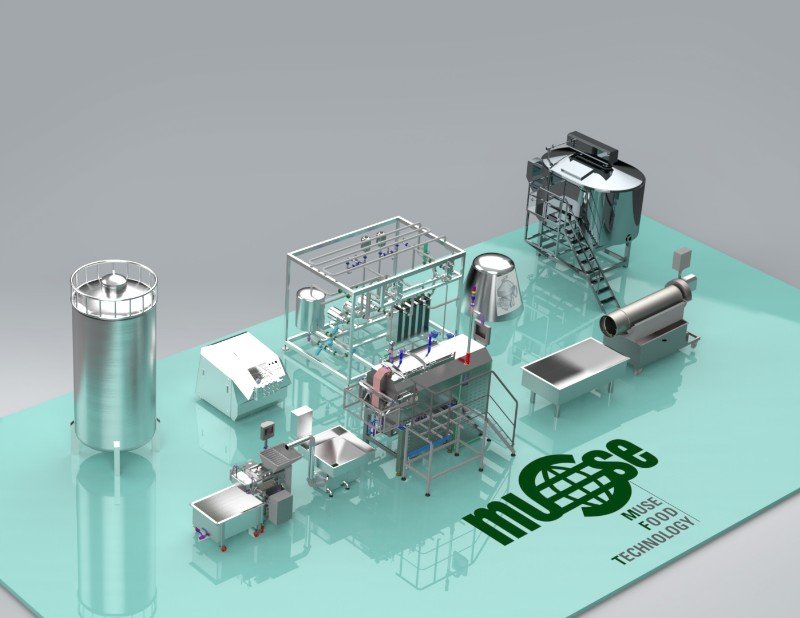

Design Phase Food Safety in Food Factories: Hygienic Design Principles Compliant with EHEDG and FDA Standards in Turnkey Projects

Food safety is critical not only for protecting consumer health but also for a brand’s reputation and business continuity. The effectiveness of food safety management systems largely depends on the hygienic design of the facility’s physical infrastructure and the equipment used. This article examines hygienic design principles compliant with European Hygienic Engineering & Design Group (EHEDG) and U.S. Food and Drug Administration (FDA) standards, starting from the design phase, particularly in turnkey food factory projects. The focal points are hygienic equipment and surface selection (3-A, DIN), process zoning, and cleanability analysis. When applied correctly, these principles are shown to reduce product contamination risk, lower cleaning costs, and guarantee regulatory compliance.

Introduction: Why is the Design Phase Critical?

In a food factory, food safety does not begin with the procedures implemented after production starts, but at the moment the project’s first drawings are made. “Turnkey” projects are integrated projects where the entire design, construction, machinery supply, and commissioning processes are managed by a single responsible party. This holistic approach offers a unique opportunity to integrate hygienic design principles into every layer of the facility (from the layout plan to the smallest gasket). An error in the design phase can lead to contamination points (hygienic traps) that are very difficult and costly to rectify later. Therefore, global guidelines like EHEDG and FDA form the project’s roadmap.

Global Standards for Hygienic Design: EHEDG and FDA

-

EHEDG (European Hygienic Engineering & Design Group): EHEDG is a Europe-based organization for hygienic design and production. It offers guidance and advice, not certification. EHEDG Documents and certified products verify that equipment is cleanable and microbiologically safe. It is a de facto necessity for market access, especially for factories exporting to the European market.

-

FDA (Food and Drug Administration) and CFR 21 Part 117: The FDA is the ultimate authority for the US market. Under Good Manufacturing Practices (GMPs), it sets requirements for the design of equipment and facilities. CFR 21 Part 117.40 mandates: “Equipment and utensils… shall be so designed as to be adequately cleanable, and shall be properly maintained to minimize the risk of cross-contamination. All surfaces that contact food must be durable, cleanable, and made of non-toxic materials.”

A successful turnkey project blends the requirements of both standards to create a flexible and safe facility that can cater to both global and local markets.

Hygienic Equipment and Surface Selection: 3-A, DIN, and Material Science

Equipment selection is the cornerstone of hygienic design. The right choice directly affects cleaning time, water/chemical consumption, and the risk of microbial harborage.

-

Material Selection: AISI 316L grade stainless steel is the gold standard for all food contact surfaces. It has high corrosion resistance, a smooth surface, and is resistant to chemicals. AISI 304 is acceptable for non-food contact surfaces (railings, platforms).

-

Surface Properties: Surfaces must have low surface roughness (Ra value). EHEDG generally recommends an Ra value of < 0.8 µm for food contact surfaces. Smooth surfaces make it difficult for bacteria to adhere and facilitate cleaning.

-

Standards and Certifications:

-

3-A Sanitary Standards Inc.: A US-based standard, particularly in the dairy, meat, and beverage industries. The 3-A symbol indicates that the equipment meets criteria for cleanability, material, and design.

-

DIN Standards: The German Institute for Standardization has a series of standards for hygienic design (e.g., DIN 11850 – pipes for the food industry). These standards ensure that fittings, gaskets, and piping systems are manufactured to hygienic specifications.

-

-

Design Principles: Equipment should not have hollow, airless spaces (dead ends), should be self-drainable, should not contain sharp corners, and should allow access for cleaning (for CIP – Clean-in-Place systems).

Zoning (Hygienic Area Classification): A Risk-Based Approach

Zoning is a fundamental strategy used to separate areas with physically different hygienic risk levels. This is the most effective way to prevent cross-contamination.

-

High Care / High-Risk Areas: Areas where cooked, fried, or packaged products susceptible to contamination are processed. These areas must have strict temperature and pressure controls, positive air pressure, and limited access.

-

Medium Care Areas: Areas where raw materials to be thermally processed or further processed are stored.

-

Low Care / Basic Hygiene Areas: Areas where raw materials are stored, packaging materials are kept, or auxiliary equipment is located.

In turnkey projects, transitions between zones must be strictly controlled with measures such as airlock systems, shoe changing and hand washing stations, and separation of personnel and material flow. Airflow should be designed from high-risk to low-risk areas to prevent particle transfer.

Cleanability Analysis: From Theory to Practice

Cleanability is the ability of an equipment or facility surface to be effectively cleaned and sanitized of microorganisms using standard cleaning and sanitation procedures. Analysis begins at the design stage.

-

Risk Assessment in Design: Each piece of equipment is evaluated for potential hygienic traps. Questions are asked:

-

“Does product accumulate at this point?”

-

“Will this bolt be contacted by the cleaning solution?”

-

“Can this pipeline be completely drained?”

-

-

CIP (Clean-in-Place) / COP (Clean-out-of-Place) Systems: The design should be integrated with CIP systems, which allow cleaning without disassembly, wherever possible. The design of CIP systems (nozzle selection, flow rate, turbulence) must also comply with hygienic principles.

-

Validation and Verification: The effectiveness of cleaning procedures must be considered during the design phase and validated upon project completion through microbial sampling, ATP swab tests, and visual inspection. This is a key FDA requirement.

Conclusion and Recommendations

The hygienic design of a food factory is not an aesthetic choice but a mandatory technical and legal requirement. Turnkey projects offer the most efficient model for implementing these principles throughout the lifecycle.

-

Project Management Advice:

-

Early Involvement: Hygiene specialists, process engineers, and food safety teams should be involved in the process from the earliest concept stage of the project.

-

Choosing the Right Partners: Equipment suppliers and contractors should be selected based on their mastery of EHEDG, 3-A, or similar standards and their past references.

-

Documentation: Compliance documents (CE, 3-A, EHEDG Certificate) for all hygienic equipment should be included in project deliveries.

-

Training: Operators who will maintain and clean the designed systems must be trained on the logic and importance of the design.

-

In conclusion, hygienic design is not just a cost item but a long-term investment that protects product quality, brand value, and operational efficiency. EHEDG and FDA standards are an indispensable guide for reliably implementing this investment.